Bagging Facilities

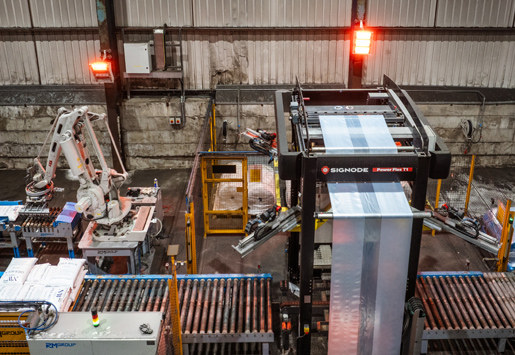

Our bagging operations provide customers with a reliable, controlled and efficient way to convert bulk materials into market-ready products. With both conventional and robotic bagging lines, we handle a wide range of materials and produce multiple bag sizes—from 10 kg and 25 kg formats suitable for shrink-wrapped pallets and domestic markets to larger industrial and agricultural specifications.

We manage the full process—from bulk intake to finished palletised product—ensuring tight control over quality, traceability and output. Our team monitors every stage of production, adjusting settings, managing feed rates and maintaining equipment to keep lines running smoothly and efficiently.

By integrating our bagging operations with on-site storage and port handling teams, we can move material seamlessly from vessel or warehouse straight into production, reducing handling steps and improving turnaround times.

In addition to our fixed bagging lines, we utilise a mobile bagging and screening plant capable of handling 600–1,000 kg batches. This flexible plant supports:

- Destuffing containers

- Rip and tip of big bags and 25 kg packs

- Product grinding

While typically based in Hull, the mobile plant can be deployed to suit operational requirements, providing customers with adaptable on-site bagging solutions wherever needed.

Operational Capabilities

- Robotic bagging line producing 10 kg and 25 kg formats

- Conventional bagging lines for flexible material handling

- Bulk intake, bagging, palletising and wrapping

- Quality, traceability and output control

- Integration with stevedoring, warehousing and transport

- Mobile bagging and screening plant for 600–1,000 kg batches, container destuffing, rip & tip, and product grinding

- Flexible deployment of mobile plant to suit operational requirements

Stevedoring

We provide stevedoring services built on precision, experience and a clear understanding of how cargo needs to move through a port. Our teams manage the full operation—from planning to final clearance—ensuring bulk and breakbulk cargoes are handled safely, efficiently and with minimal downtime…